Many metallic objects are produced by pressure die-casting. One of those metals which are ideally suited for this process is magnesium. The demand is growing with the automotive industry and its continuous demand for lightweight construction acting as a driver of innovation. Also other industries whose products are in demand for a low weight and a favourable strength weight ratio are boosting the demand.

Advantageous characteristics

Magnesium has a specific density of 1.74 g/cm³ and is therefore one third lighter than aluminium with 2.75 g/cm³. Pure magnesium, however, is relatively soft. In order to use it as a construction material it is alloyed with elements like aluminium, zinc, manganese and silicon. Depending on the composition, the tensile strength of these alloys is between 200 to 310 MPa being therefore in a range which is typical for aluminium alloys. The same can be said of the strength weight ratio. Furthermore, magnesium alloys demonstrate favourable elongation and impact strength values, the damping characteristics and the electromagnetic shielding are very good. Magnesium materials are easy to process and can be completely recycled. When processing magnesium materials, however, it has to be considered that magnesium in melted and pulverized form exhibits with oxygen a strong exothermal reaction. This can cause explosion-like deflagrations. The surface of a magnesium melt has therefore to be protected against the air by a protective gas atmosphere. Also when machining magnesium parts certain protective measures are necessary.

Magnesium pressure die-casting

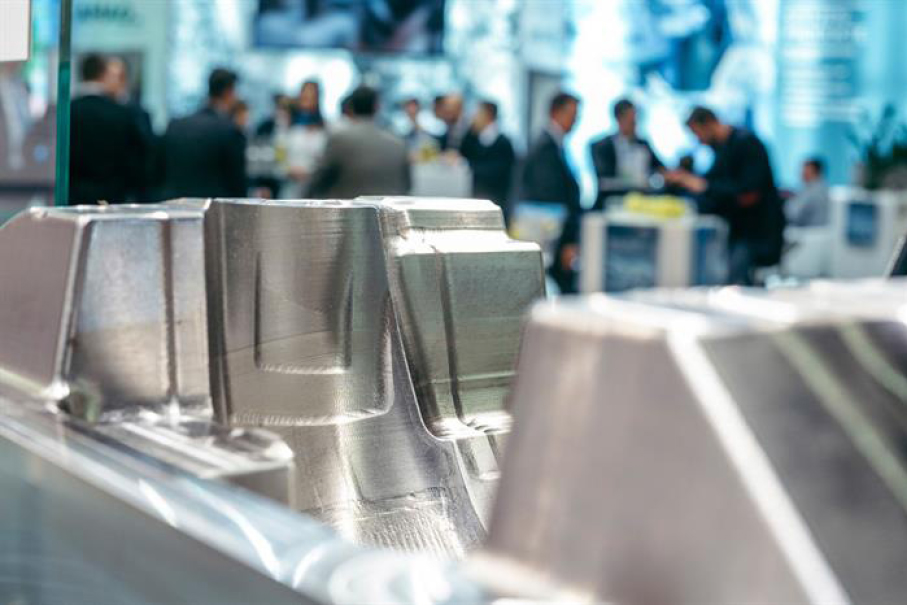

Magnesium melts at 650°C, is then a very thin fluid and lightweight. Therefore, magnesium materials are ideally suited to be shaped by pressure die-casting. As the thinbodied melt fills very quickly the mould, short cycle times and therefore a high productivity are possible. The castings can be designed thin-walled. “However, magnesium pressure die-casting requires a particular knowledge”, says Hartmut Fischer, managing director of the STIHL Magnesium Druckguss Prüm-Weinsheim company. “In order to take maximum advantage of the material properties it is necessary to ‘think in terms of magnesium'.” This begins with the design of the castings. Consequently, the company succeeded to replace an aluminium protective cover for a gasoline-driven angle grinder by a completely re-designed magnesium part made by pressure die-casting. The cover was originally made from an aluminium sheet and weighing 1,040 g, the new cover weighs only 690 g – a weight reduction of 34%. Simultaneously, the manufacturing costs could be halved. Hartmut Fischer, whose company is among the leading magnesium pressure die-casting foundries throughout Europe, sees even much application potential for magnesium pressure die-casting because: "Wherever weight is important there is an increasing pressure to reduce weight”. This is the case with electrically powered vehicles, for example. The weight increase caused by the batteries could be reduced by components made by magnesium pressure die-casting, for example the battery cover. The industry could open up further potential through new magnesium alloys which withstand higher operating temperatures and offer an improved creep resistance which is very important for screw connections. The trends include also the combination of different lightweight materials. Parts made from magnesium are combined with plastics or composite materials by casting or gluing in order that the advantageous properties of all involved materials can be exploited to an optimal extent.

Applications

Typical parts made of magnesium pressure die-casting which are used in the automotive industry are gear box housings, housings for electronic components, supporting structures of instrument panels, components of seats, steering wheels, rims, door reinforcements, tailgates and chassis components. Also housings for mobile phones and flat screens as well as crankcases and covers for handheld tools for forestry and garden such as chainsaws, brush cutters, hedge trimmers, angle grinders and drilling machines are made of magnesium pressure die-casting.

The trade fair EUROGUSS 2018

An insight into the state-of-the-art in pressure die casting and suggestions as to how die-casting foundries can strengthen and expand their market position will be provided at the EUROGUSS 2018 – International Trade Fair for Die Casting: Technology, Processes, Products in Nuremberg, Germany, 16 - 18 January 2018.

Fig: The protective cover of this angle grinder is made from magnesium pressure die-casting and weighs 690 g. The changeover from the previous version made from an aluminium sheet (1,040 g) resulted in a weight reduction of 34% and the halving of the manufacturing costs.